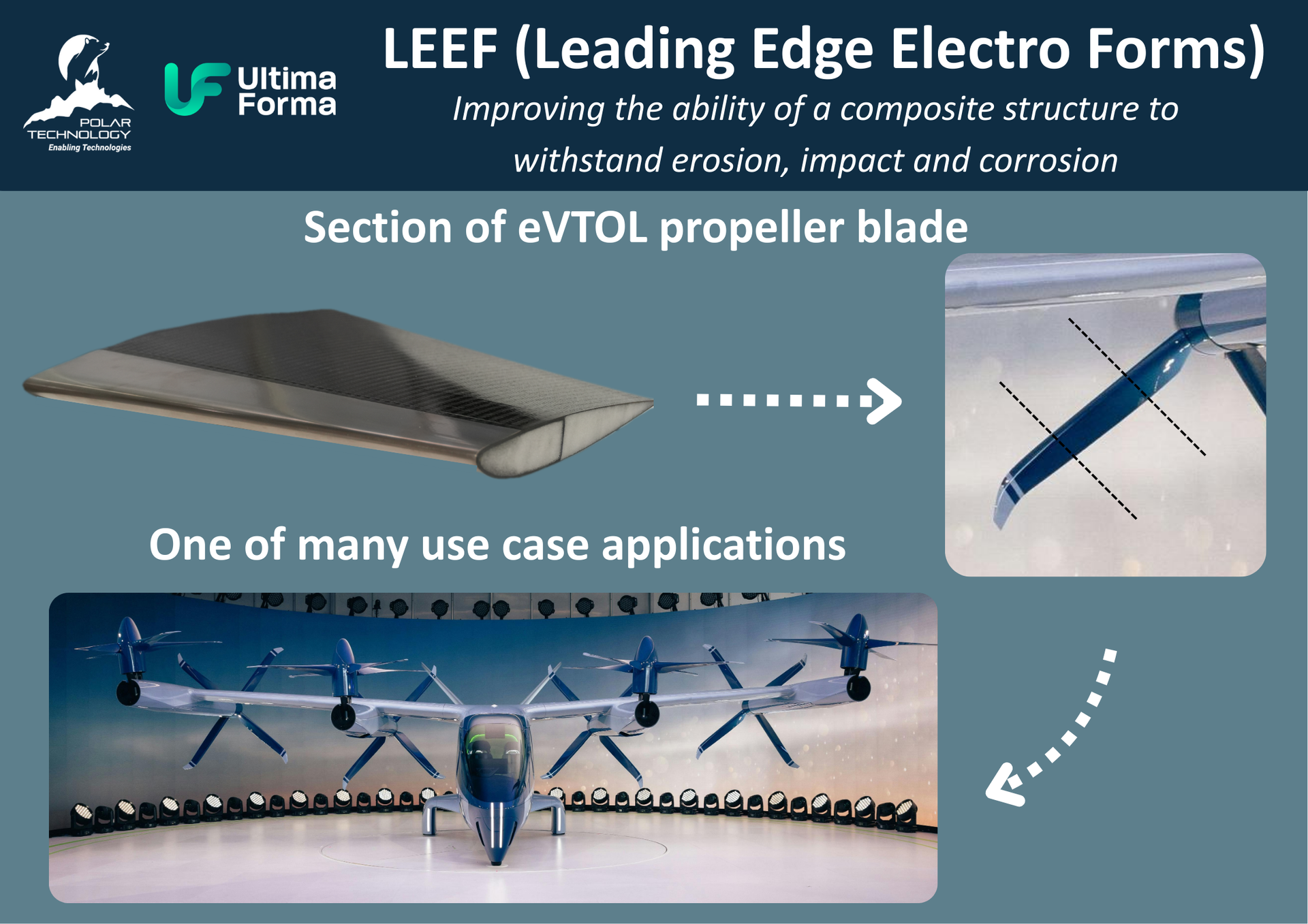

Ultima Forma and Polar Technology’s leading edge protection layer enhancing durability for aerospace and defence applications

Last year, Ultima Forma and Polar Technology announced the launch of the LEEF (Leading Edge Electro Forms) project, collaborating to improve the ability of a composite structure to withstand erosion, impact and corrosion in extreme operating conditions.

The project has gone from strength and strength and is now attracting interest from leading Aerospace and Defence organisations, who are exploring potential applications for the technology.

Ultima Forma have developed the protection layer through a process of electro-forming, which involves electric currents depositing a thin layer of metal onto a substrate. Polar Technology are experts in design and manufacture of critical composite products and are working closely on the best method to integrate this electroform into the structure.

All aspects of the process can be carefully controlled, with the thickness and dimensions being tailored depending on the application. The ambitions behind the project are to develop a UK-based manufacture and distribution network for leading edge protection solutions including the manufacture of the composite structure itself which will ultimately shorten and simplify the supply chain process.

A number of milestones have been hit since the project launched, including the Nickel-Cobalt LEEF layers maintaining exceptional hardness when tested up to 900°C and beyond 1000+ hours of ASTM B117 salt spray testing, delivering unparalleled performance for high-temperature platforms and mission-critical components.

Scalable manufacturing of parts is underway, with the electroformed leading edges integrating seamlessly with composite aerofoils as co-moulded or secondary bonded structures, enabling faster builds and retrofit flexibility. Three key use cases have been identified as ideal demonstrators of the technology: rotor and propeller blades for eVTOL and UAV applications, aerofoils for turbine inlets, and outlet guide vanes for aircraft engines.

All three cases are based on geometries provided by leading OEM customers in the aerospace and defence industries, which illustrates the planned routes to market. From the smallest ISR drone to the largest tactical transport, LEEFs deliver lightweight, high-durability protection against rain, ice, sand and bird strikes.

Daniel Chilcott, Business Development Director at Polar Technology said “Its fantastic to see the progress with this project and close collaboration between Polar Technology and Ultima Forma leading to solutions that could really benefit the industry. We know the market is striving for scale on a competitive level without compromising on performance or quality. This technology and collaboration has the potential to make this a reality.”

Steve Newbury, CEO at Ultima Forma said “The LEEF project has already produced and tested parts to prove out the potential in this flexible barrier technology. Bringing together lightweight composites with thin tailor-made electroformed protection delivers a unique sovereign capability for the UK’s aerospace and defence sectors”.

Read the original article on the project here.

Or to speak to our team about a potential end application for the technology, click here.